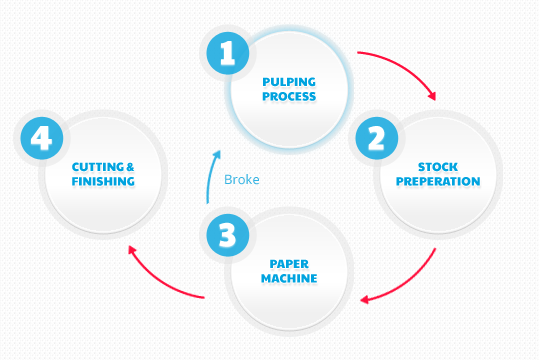

Technology

Step 1 : Pulping Process

This is the first stage of the paper making process where our raw materials are mixed with water and slush to a low consistency. Our raw materials consist of 100% recycle fiber which is collected mostly from local sources. We import high quality waste paper from around the world to maintain the quality parameters. We have recently upgraded our existing pulper to high consistency pulper to achieve a better result. It also improves the quality of the fiber as it removes contaminants as this stage itself.

Step 2 : Stock Preparation

After the pulping stage the stock needs to cleaned to free itself from contaminants and to get it up to the quality that we require. We are proud to have the latest and the most extensive stock preparation system in the industry which helps us to maintain a good quality pulp stock. Each layer consists of their own cleaning systems like course screening machines, centri-cleaners, dispersers and thickeners. Additionally, all three streets have consistency regulators which are present in two stages which help to regulate the consistency as per requirement of paper/board machine.

Step 3 : Paper Machine

Our machine consists of wire and de-watering elements.

Step 4 : Cutting & Finishing

Our cutting section comprises of imported cutters to cater the size requirements of our customers. These cutters are of very high quality resulting in little or no size variations. In addition to this we also have a rewinder to cater to the needs of customers who require paper in reel forms. After cutting the paper is packed according to the needs of customer and is dispatched.